Recently, the paper entitled“Developing a Vacuum-Assisted Gas-Permeable Membrane Process for Rapid Ammonia Recovery and CO2 Capture from Biogas Slurry”was published by research group led by Professor Yan Shuiping of HZAU & College of Engineering in the ACS Sustainable Chemistry & Engineering, an internationally academic journal of Energy and Environmental Engineering. A new technology has been proposed in the paper that a low carbon footprint biogas slurry (BS) ammonia nitrogen gains rapid recovery and resource utilization. This technology can achieve rapid ammonia nitrogen recovery and CO2 separation without changing the pH value of the BS. At the same time, it can also avoid foaming and introduction of oxygen in the traditional ammonia nitrogen separation. BS reuse offers the possibility to provide new ways for resource recovery and carbon capture.

The BS, produced by anaerobic fermentation of livestock and poultry manure, contains high-concentration ammonia nitrogen, and its direct utilization may cause a large amount of nitrogen loss, which in turn will increase the particulate matter (such as PM2.5) in the air, eutrophication of water bodies, and even groundwater pollution and other environmental issues. Therefore, it is necessary to recycle most of the ammonia nitrogen before the BS is utilized. In addition, in the anaerobic fermentation process of BS reflux, high ammonia nitrogen concentration can easily cause fermentation failure, so ammonia nitrogen must be removed before the BS is reused. The ammonia nitrogen recovered from the BS is not only an important fertilizer resource, but also an important chemical raw material. However, most of the current researches on ammonia nitrogen recovery focus on the improvement of recovery efficiency and feasibility, and there is less involved in the recovery and utilization of ammonia nitrogen with low carbon footprint.

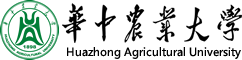

A novel vacuum-assisted gas-permeable membrane (VGPM) process was proposed for the separation and recovery of ammonia nitrogen in BS, which can realize the rapid recovery of ammonia nitrogen and the capture of CO2. In the study, a first-order reaction kinetic model was used to verify the efficiency of the decompression-assisted gas-permeable membrane process for ammonia nitrogen recovery. Its first-order reaction kinetic constant reached 0.28 h-1, far exceeding the individual membrane absorption and thermal removal techniques. Through the mass transfer characteristics of ammonia nitrogen and water, the operating parameters of high efficiency and low energy consumption were achieved, the mass transfer mechanism of ammonia nitrogen and CO2 in this process was revealed, and the long-term stability of the process was verified. According to the principle of full life cycle assessment, the greenhouse gas (GHG) emissions of this process are calculated to be -1.6 kg-CO2 / kg-N, which indicates that the process can achieve a net negative emission of CO2.

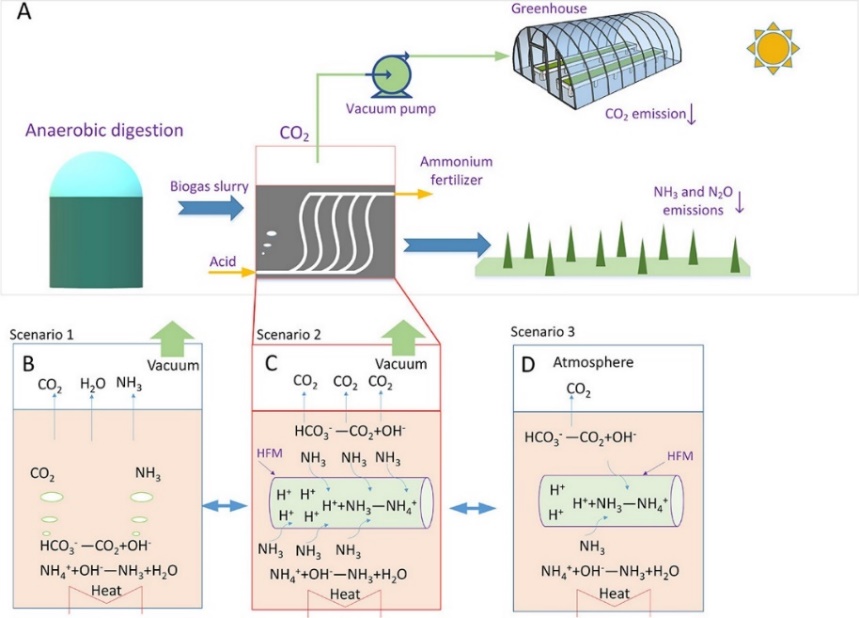

Focusing on the recovery of ammonia nitrogen from BS after anaerobic fermentation producing renewable CO2 absorbent (RAA), this research further utilizes agricultural waste such as straw, livestock and poultry manure as raw materials for processing and preparing for CO2 capture. The integrated alcohol amine absorbent, amino acid salt absorbent and inorganic salt absorbent provide sufficient green raw material for the recent industrialized use of chemical absorption to capture CO2. At the same time, in terms of carbon emission reduction, quality improvement and efficiency improvement of biogas projects, the research has proposed to use renewable ammonia as a link, while achieving nutrient recovery, CO2 capture, and biogas purification. Compared with the traditional process, the new type of process system can realize the increase of the system's economic profit and the net negative CO2 emission through the reasonable allocation of resources and the cascade utilization of energy. Relevant research results have also been published in international journals such as ACS Sustainable Chemistry & Engineering, Environmental Science & Technology, etc.

Dr. He Qingyao, a lecturer in HZAU & College of Engineering, and Dr. Xi Jiang from Biogas Institute of Ministry of Agriculture are co-first authors, and Professor Yan Shuiping is the corresponding author of the paper. This research gained financial supports from the National Natural Science Foundation of China (NSFC) (nos.51376078, 51676080), the Fundamental Research Funds for the Central Universities (nos. 2662018PY046,2662018QD028), and the Key Laboratory of Development and Application of Rural Renewable Energy, Ministry of Agriculture and Rural Affairs, China (2018-003).

Professor Yan's team has been devoted to the research of ammonia nitrogen removal and resource utilization in BS in recent years, and has carried out continuous and in-depth research on the efficient separation of ammonia nitrogen in BS and the development of BS-based renewable CO2 absorbent systems.

Source: https://pubs.acs.org/doi/10.1021/acssuschemeng.9b04873

Translated by: Jiang Tingting

Proofread by: Guo Haiyan